The Jinnaisi Nano Grinder is a specialized equipment developed for the preparation of nanomaterials. The equipment consists of a dispersion system, a feed system, a grinding system, a cooling system, a circulation system, and a control system. It is easy to operate and has high grinding efficiency. It is suitable for the preparation of various nano materials and has the characteristics of low energy consumption, low noise and no pollution.

The Jinnaisi nano-grinding machine can adapt to the high viscosity and high solid content of the material during the grinding process, while achieving the low particle size requirement. The equipment itself has the characteristics of high grinding efficiency, good stability and small loss of grinding beads. Soon it will be applied to the laboratory's research and development needs for new materials, and it can also be applied to industrial production.

Configuration parameters:

Rotor material: zirconia / silicon carbide

Cylinder material: zirconia / silicon carbide

Sealing method: double-face mechanical seal, designed for fine grinding beads and nano-slurry, easy to install and replace.

Separator: large-area tubular grid with a minimum clearance of 0.05mm

Feed pump: pneumatic diaphragm pump, screw pump or gear pump

Grinding medium: yttrium stabilized zirconia beads / silicon carbide beads, minimum diameter 0.1mm

Control system: PLC control system, one-button start, easy to control

Application areas:

Printing inks Pharmaceuticals Biosciences New energy batteries Low-temperature sintered ceramics Non-crystalline metals Pigments/dyes High-grade paints Cosmetics Foods Nano-powders Pesticides

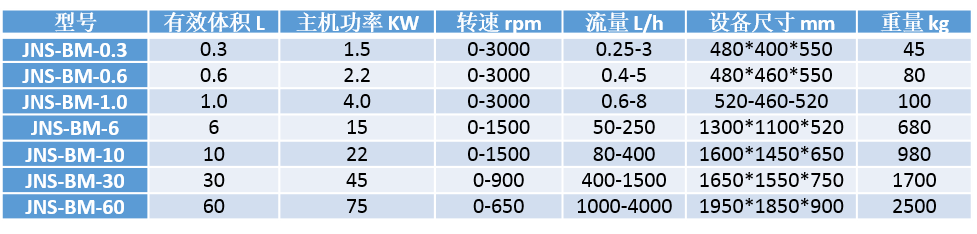

technical parameter: